Preheater heater 220V with pump: installation and circuit

In the winter, the driver lurks a lotproblems. First of all, they are connected with a bad start of the car engine. In order to solve this problem, experts advise installing special pre-start heaters. These devices are able not only to guarantee the start of the engine in any weather, but also significantly reduce the emission of exhaust gases into the atmosphere.

Thus, the driver has the opportunitytake care of the environment. Some models pre-start heaters due to its action save the owner quite a lot of fuel. Direct friction between the engine parts is greatly reduced. Along with this, the wear of important elements is much slower, which positively affects the performance of all the nodes.

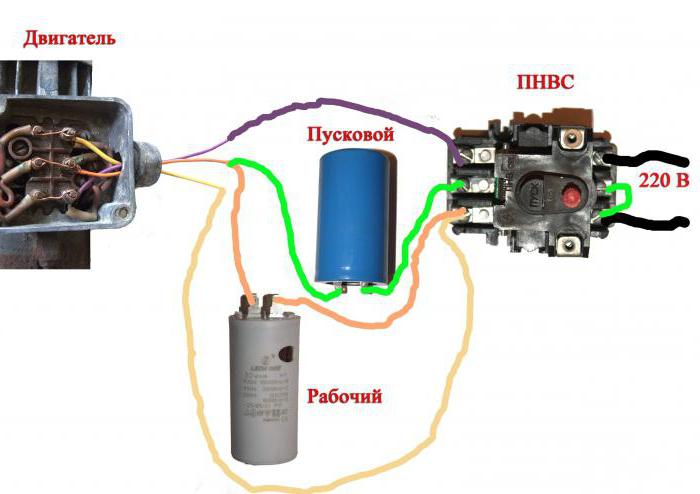

Diagram of conventional preheater

Schematically engine preheater220V with a pump can be imagined as a tubular electric heater, which is enclosed in a housing. At the bottom of the structure is a small gasket that serves as a seal. To control the temperature in the system there is a thermostat. Under the top cover of the device there is also a gasket. The pump in the mechanism is electromagnetically mounted. Under its base there is a rubber ring. In addition, an impeller is installed in the lower part of the device, to which the flange is connected.

How it works?

When the engine preheater 220V withThe pump is connected to the system, electricity is supplied to it. As a result of this process, a tubular electric heater is turned on. Its main task is to raise the temperature of the antifreeze. The heated liquid then enters the cooling system. This happens with the help of a pump, as well as an impeller, which is installed in the device.

Thus, a constantcirculation in the system. The engine warms up slowly and evenly. In order to maintain the optimum temperature in the system, there is a thermostat. If necessary, it is able to open the contacts, and no voltage will be applied to the tubular electric heater.

Correct installation of the device

How to Install a Preheating Heaterengine? Answering this question, it should be understood that much depends on its modification, but there are general provisions on this matter. First of all, it is important to remember that the device must be connected to a single-phase network. In this case, the contact must be grounded. This is done by means of a circuit breaker, which is protected against current.

Also some advise on installationequipment use a shutdown system. This device will significantly protect the installation process of the model, and the risk of electric shock will be minimal. Any shorting in the wiring can lead to a fire. Considering this, during work, it is not necessary to touch non-insulated sections of equipment. When starting the pre-heater, it is important to inspect the cooling system. The device must be connected from the side of the cylinders. In this place there must be a branch pipe, the diameter of which is 20 mm.

Then place the device in a horizontalposition. Ultimately, it must be below the level of the radiator. This is done in order to prevent the device from being airborne. The fixing point can be changed if necessary, by using an additional hose. As a rule, it is added to the model. After connecting the device, it must be fixed to the body. In some cases, this is quite problematic. However, it is considered a gross mistake to fix the pre-heater to the silencer manifold. In most cases this is unsafe and can lead to a fire in the car.

Package Contents

In the standard set of pre-startthe heater can be found brackets, as well as bolts. For better fixing of the device an intermediate sleeve is applied. The bracket, as a rule, is supplied by the manufacturer one. In order to secure the engine preheater 220V with the pump, there are two bolts in the upper part of the engine, as well as nuts.

For them, the kit includes a set of washers, asordinary, and rover. In order to connect the tee to the cooling system, there are fittings. Usually it is possible to meet in the complete set immediately spare. They are supplied with the marking. If we consider models with a voltage of 220 V, then the choke must be labeled K14. In this case, its diameter is indicated. In order to secure the device, there are clamps. In addition, you can find a small sleeve in the kit. In turn, the clamps are worm, as well as for screeds. They are made, as a rule, from nylon and are quite elastic.

What determines the power of the preheater?

First of all, the capacity of the pre-startThe heater is connected to the maximum frequency of the device. Usually this parameter is within 50 Hz, however, its deviations are possible. Additionally, the piston diameter is taken into account. Its size ultimately affects the flow velocity of the flow.

The higher the operating power of the device, the fasterthe temperature is dialed. Usually in the engine, the antifreeze is capable of heating up to 60 degrees. The average heating time is 3 minutes. In this case, much also depends on the location of the pre-heater. As stated earlier, it must be securely fixed and not blown.

Important Device Settings

Important parameters of pre-heatershould be attributed power. This is measured in kW. If we take a model with a power of 1.5 kW, the heating time of the antifreeze will be approximately 3.5 minutes. If the above figure is 2 kW, then the required temperature can be reached in 3.2 minutes.

In this case, the type of current is taken into account, and also the limitingfrequency, which is measured in Hz. It depends on the temperature of the thermostat. The indicator of the circulation flow is measured in liters per second. It is largely related to the diameter of the inlet, as well as the outlet. On average, the nozzles are made with a size of 12 mm. In this case, the dimensions of the device itself can be very different. On average, the preheater length is 150 mm, width - 90 and height - 90 mm.

Device protection is classified bydegrees. The most common models are marked "IP34". This inscription says that the device is safe for human health, and cases of short circuits are virtually eliminated. In addition, the customer from the parameters must check the plugs. If we talk about Russian manufacturers, they equip their models according to European standards. On average, the mass of the device fluctuates around 1 kg. A good pre-start heater of the 220V engine with a pump for the buyer in 4 thousand rubles will work.

Scheme of preheating heater "Webasto"

The "Webasto" model has a standardinstallation diagram. The engine preheater in the central part has a tubular electric heater. For its connection with the impeller, a special bushing is installed. The thermoregulator in this case is located at the top of the structure. The fuel is supplied from the side of the cylinders.

Thus, the circulation flow of the devicepretty high. The main chamber of the device is made of stainless steel, so the temperature keeps high. There is a pump under the control unit. As a result, the power of the preheater can be adjusted.

Device model "Webasto 220V"

Engine preheater Webasto 220Vfrom other devices is characterized by a volumetric heat exchanger. It is located immediately above the tubular electric heater. In this case, the piston is of a small diameter. However, the impeller of the place takes a lot. Fuel supply to the system is regulated by means of a special sensor.

In order to change the limit temperatureliquid, there is a control unit. In this regard, many models are equipped with a self-diagnosis system. In addition, the preheater of the Webasto 220V engine is available with fans. In this case, they cope with overheating of the main camera of the device.

How to install the Atlant model?

In order to properly install the pre-startengine heater "Atlant", it is necessary to inspect the inlet, as well as the outlet opening. To do this it is necessary according to the scheme that is applied to the device. The location of the installation is determined based on the location of the heater. In any case, the device should be below its level. Then disconnect the pipe from the system.

After that, all coolant must drain. Only then can you do the input connection of the device. In this case, the preheater hose must not be clamped. The outlet connection is connected to the last. At the end of the operation, the cooling system is refilled with liquid. When the engine warms up well, the device can be started.

Consumer feedback on the Atlant 220V model

This engine preheaterthe reviews are good. Many buyers praise him for having a solid body. It is made, as a rule, from anodized aluminum. Directly the heating process occurs evenly. The power of the device is acceptable, and in the installation the engine preheater with the pump is fairly simple. It will cost him on the market an average of 3 thousand rubles.

Characteristics of preheater "VAZ-2107"

Engine preheater "VAZ-2107"it is usually produced with a maximum power of 1.5 kW. The operating frequency must be at least 45 Hz. The performance of the pump depends more on the location of the device. If this figure is below 4 liters per minute, then the configuration is clearly not suitable. In addition, in this situation, you should take into account the height of the pumping. As a rule, this parameter lies in the region of 1000 cm. The maximum temperature thus reaches 70 degrees.

The device models of the company "Eberspecher"

Models of this trademark in the first placediffer in acceptable power. Pump Performance The Eberspacher engine preheater has an average of 4.5 liters per minute. The degree of protection is indicated with the marking "ИП24". According to the dimensions of the model you can choose a variety. The maximum pumping height of the liquid is 90 cm. The temperature regulators are set fairly high, and there are no problems with them. The average pre-start heaters in the region of 4000 rubles stand.

What "Eberspecher Hydronic "?

"Hydronic" - this pre-heater heater of the newseries of the company Eberspecher. A distinctive feature of it is increased productivity. Serving this model is capable of considerable time. Of the disadvantages, it should be noted quite a quick heating. At the same time, a large pump can create a pressure in the system of over 3 atm.

As a result, the hoses are largeload. The heat exchangers in this model are made of stainless steel. The control units of the manufacturer are provided with different operating modes. In addition to the temperature sensor, a protection system is installed at the top of the structure, which saves the engine from overheating.

</ p>